MIWA 3800: Difference between revisions

No edit summary |

No edit summary |

||

| Line 50: | Line 50: | ||

'''Notes''' | '''Notes''' | ||

* To pick the 3800, both the magnetic and dimple components must be properly aligned at the [[shear | * To pick the 3800, both the magnetic and dimple components must be properly aligned at the [[shear line]]. | ||

* Impressioning and key bumping are possible given a blank key with the correct magnetic elements. | * Impressioning and key bumping are possible given a blank key with the correct magnetic elements. | ||

Revision as of 18:54, 26 January 2012

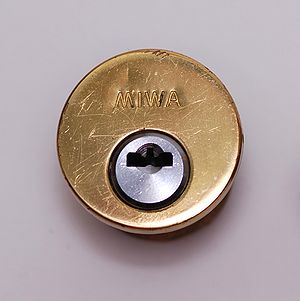

MIWA/Anker 3800

| MIWA/Anker 3800 | |

| |

| Name | MIWA/Anker 3800 |

|---|---|

| Manufacturer | MIWA |

| Lock Type | Cylinder |

| Lock Design | Hybrid, Pin-tumbler, Magnetic |

| Related Locks | |

| MIWA EC | |

The 3800 is a hybrid lock that uses magnetic and dimple components. It is made by MIWA (Japan) and Anker (The Netherlands). The 3800 is one of the few magnetic locks to be widely used around the world in high-security installations, particularly in Europe and Asia.

The 3800 supercedes the MIWA EC. It is also available in a magnet-only configuration, including a cam lock version. The magnet-only version of the lock is considered mroe reliable in harsh environments due to the absence of accesible or moving parts in the keyway.

Principles of operation

The 3800 uses four pin-tumblers arranged in a dimple configuration and four magnetic sliders as locking components. To open the lock, all components must be properly aligned at the shear line by the correct key. The pin-tumblers are raised to their proper heights, and the magnetic sliders are pulled into the plug by the magnets in the key.

The 3800 uses a variety of security pin designs on the driver pins to deter lockpicking, decoding, and overlifting.

Security pins used in the 3800.

Notes

- Newer 3800s may use additional pin stacks.

Vulnerabilities

The 3800 may be vulnerable to one or more of the following:

Notes

- To pick the 3800, both the magnetic and dimple components must be properly aligned at the shear line.

- Impressioning and key bumping are possible given a blank key with the correct magnetic elements.

Disassembly instructions

- Remove the cam and C-clip.

- Remove the chamber casing for the pin-tumblers and remove the spring and pins.

- Insert the working key and extract the plug.

Notes

- Do not remove the plug when it is rotated at 90°; the driver pins will get stuck in the channels where the magnetic components protrude.

- If you cannot remove the pin-tumblers from their chambers, rotate the plug 180° before extracting the plug.

- Do not remove the key from an exposed plug without holding the sliders in place. The change in magnetic field and spring pressure will eject the sliders (forcibly!).

- A standard size (1/2") plug follower will not fit in the 3800.

Gallery

References