Rosengrens RKL-10: Difference between revisions

m (added catregory:rosengrens) |

m (small edit to test settings) |

||

| (12 intermediate revisions by 2 users not shown) | |||

| Line 15: | Line 15: | ||

| spec_comp = 9 | | spec_comp = 9 | ||

}} | }} | ||

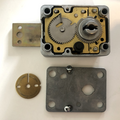

The '''RKL-10''' is a [[disc-detainer]] lock used on [[safe]]s made by [[Rosengrens]]. | |||

| Line 21: | Line 23: | ||

== Principles of operation == | == Principles of operation == | ||

This lock has a double circular lever one pack consisting of 9 code wheels and 2 driver wheels. The other pack engages with the cuts on the key, drives the code pack and a corresponding fence that will go into the true cuts and then allows the bolt to be moved into the open or closed positions. The key has 9 different cuts (1 passive cut called AB). Cuts 1-4 are on the A-side of the key. Cuts 5-8 are on the B-side of the key. No cut on side A is called A1. Deepest cut on side A is called AB. AB is a passive cut. An AB cut meant that the next active cut is B5-B8. There is a transport key which being a no-cut is all A1's. | |||

Only one side of the key is ever active in each cut position. Cuts on the opposite side of the key in these positions are only to make visual inspection harder. There are two versions of this lock. Only the code wheels differ. Version one takes longer to decode although decoding is possible the procedure is different. | |||

== Gallery == | == Gallery == | ||

| Line 36: | Line 38: | ||

File:RKL10_key_in_lock-Idanhurja.png | File:RKL10_key_in_lock-Idanhurja.png | ||

File:RKL10_keyhole_curtain_turned-Idanhurja.png |RKL-10 keyhole with curtain rotated. | File:RKL10_keyhole_curtain_turned-Idanhurja.png |RKL-10 keyhole with curtain rotated. | ||

File:RKL10_MakeUpKey_TechnicalEntry.jpg |RKL-10 Make Up Key and Key Gauge. | |||

</gallery></div> | </gallery></div> | ||

| Line 42: | Line 45: | ||

*Lockpicking | *Lockpicking | ||

*Decoding | *Decoding | ||

The decoding process for this high security lock was first designed and developed by a company called Technical Entry in 2012. | |||

The process has three phases: | |||

*1 - Determine whether the true cut for each lever is an odd or even number (1,3,5,7 or 2,4,6,8) | |||

*2 - Use the anlalysis sheet to determine true or false gates | |||

*3 - test possible combinations and open the lock | |||

Time to decode using this technique ranges from about 12-40 minutes. The key code affects the decoding time. | |||

The procedure is possible due to the design of the code wheels following a known pattern thus true code is possible to deduce via testing in a much reduced code space. | |||

== External links == | == External links == | ||

| Line 48: | Line 59: | ||

* Idanhurja [https://www.youtube.com/watch?v=DB4xi3W_O-4 Operation of RKL10 demonstrated using a cutaway lock] (video) | * Idanhurja [https://www.youtube.com/watch?v=DB4xi3W_O-4 Operation of RKL10 demonstrated using a cutaway lock] (video) | ||

* Fey, Han. [https://toool.nl/images/7/72/Abloypart4.pdf Abloy Special Products (Part 4)] | * Fey, Han. [https://toool.nl/images/7/72/Abloypart4.pdf Abloy Special Products (Part 4)] | ||

* Technical Entry [https://technicalentry.de/rosengrens-the-european-sicherheitsstufe-iv-tresor-ohne-schluessel-oeffnen/ RKL10 opening ] (German language) | |||

== See also == | == See also == | ||

Latest revision as of 04:10, 5 January 2025

Rosengrens RKL-10

| Rosengrens RKL-10 | |

| |

| Name | Rosengrens RKL-10 |

|---|---|

| Manufacturer | Rosengrens |

| Lock Type | Safe lock |

| Lock Design | Disc-detainer |

| Specifications | |

| # of Components | 9 |

| Component Type | Disc-detainer |

The RKL-10 is a disc-detainer lock used on safes made by Rosengrens.

Principles of operation

This lock has a double circular lever one pack consisting of 9 code wheels and 2 driver wheels. The other pack engages with the cuts on the key, drives the code pack and a corresponding fence that will go into the true cuts and then allows the bolt to be moved into the open or closed positions. The key has 9 different cuts (1 passive cut called AB). Cuts 1-4 are on the A-side of the key. Cuts 5-8 are on the B-side of the key. No cut on side A is called A1. Deepest cut on side A is called AB. AB is a passive cut. An AB cut meant that the next active cut is B5-B8. There is a transport key which being a no-cut is all A1's. Only one side of the key is ever active in each cut position. Cuts on the opposite side of the key in these positions are only to make visual inspection harder. There are two versions of this lock. Only the code wheels differ. Version one takes longer to decode although decoding is possible the procedure is different.

Gallery

Vulnerabilities

- Lockpicking

- Decoding

The decoding process for this high security lock was first designed and developed by a company called Technical Entry in 2012.

The process has three phases:

- 1 - Determine whether the true cut for each lever is an odd or even number (1,3,5,7 or 2,4,6,8)

- 2 - Use the anlalysis sheet to determine true or false gates

- 3 - test possible combinations and open the lock

Time to decode using this technique ranges from about 12-40 minutes. The key code affects the decoding time. The procedure is possible due to the design of the code wheels following a known pattern thus true code is possible to deduce via testing in a much reduced code space.

External links

- Ларин Олег (Larin Oleg) OB ROSENGRENS RKL10 (video)

- Idanhurja Operation of RKL10 demonstrated using a cutaway lock (video)

- Fey, Han. Abloy Special Products (Part 4)

- Technical Entry RKL10 opening (German language)

See also

| This article is a stub. You can help Lockwiki by expanding it. |